CNC Horizontal Milling of Aluminum Mounting Block Component for the Defense Industry

PORTFOLIO: Mounting Block

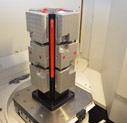

Edgar Industries was asked to improve upon the manufacturing time and efficiency of a particular aluminum mounting block already in production for a DoD application. Our client manufactured 2 blocks at a time, the whole process taking 26 minutes. Through our own examination of customer-supplied print and 2D CAD drawing designs, we developed a production strategy that would speed production without sacrificing design quality.

By way of a MAZAK NEXUS 5000-II horizontal milling machine with a 160 too changer and a two-pallet loader, we were able to build the 6061-T6 aluminum blocks with perfect tolerance range. Using two Chick Work Holding Systems – one mounted on each of the pallets – we were able to machine 4 blocks in under 20 minutes. In addition, we were able to “keep the spindle turning” by loading and unloading one Chick Work Holding System, while the other pallet was in the machining chamber

For other examples of our work for high-tech aerospace and DoD clients, contact Edgar Industries today, or consult our website further.

Specifications for this CNC Milled Aluminum Mounting Block

Product Description

-

This aluminum mounting block is used for a DoD application Customer manufactured 2 at a time and took 26 minutes. On EDGAR’s new MAZAK nexus 500-II using the Chick Work Holding System, we are able to machine 4 in less than 20 minutes.

The Nexus has a two-table loading station, which allows parts to be loaded and off loaded while machining continues.

Capabilities Applied/Processes

-

Horizontal CNC Milling

- 4 Parts Per Fixture

- Less than 5 Minutes Per Part

Equipment Used to Manufacture Part

-

MAZAK NEXUS 5000-II Horizontal Milling Machine

- 160 Tool Changer

- Two Pallet Loader

Chick Tooling

- Maximum Work Piece Exposure

- Quick Changeover

Overall Part Dimensions

-

4.5 inches X 4.5 inches X 2.0 inches

Tightest Tolerances

-

NILL

Material Used

-

6061-T6 Aluminum

Max Material Finish

-

NILL

In process testing/inspection performed

-

NORMAL

Industry for Use

-

Department of Defense

Delivery Location

-

Saxonburg, Pennsylvania

Standards Met

-

Customer supplied print, 2D CAD drawing

Product Name

-

Block Component